Utilizing the UX design process to produce 100 masks for

medical staff, essential workers, and loved ones.

Utilizing the UX design process to

produce 100 masks for medical staff,

essential workers, and loved ones.

Utilizing the UX design process

to produce 100 masks for

medical staff, essential

workers, and loved ones.

By conducting a design sprint, I strategized how I could utilize the resources and materials I owned to help produce mass quantities of fabric masks.

- TIMELINE

- 1 week Design Sprint

- 2 week Bulk Production

- ROLE

- UX Researcher

- UX Designer

- Product Developer

- TOOLS

- Adobe Illustrator

- Paper & Pencil

- Sewing Machine

- Cotton Fabric

- Spandex Fabric

- METHODS

- User Research

- Sketching

- Pattern-making

- Construction

- Rapid Prototyping

- A/B Testing

- Interactive Testing

PROBLEM STATEMENT

The shortage and long lead‑time for face masks is preventing people from staying safe against the COVID‑19 pandemic.

HYPOTHESIS

By producing reusable fabric face masks, people are able to protect themselves against the virus, while operating their day to day activities.

Here's the Scope: Users are at risk due to the limited

availability of face masks

Here's the Scope: Users are

at risk due to the limited

availability of face masks

What are the users' painpoints and expectations?

I conducted 4 remote user interviews to better understand users' painpoints and expectations surrounding face masks. Users ranged between ages 18‑62 and worked in various industries, with some users required to go into work and some able to work from home.

PAINPOINTS

- shortage of face masks

- order and ship time is too long

- the masks are not fitted and are uncomfortable

- no filter pockets

- one-time use only

EXPECTATIONS

- reusable and washable face masks

- filter pocket

- flexible nose bridge

- comfortable ear straps

- easy to wear

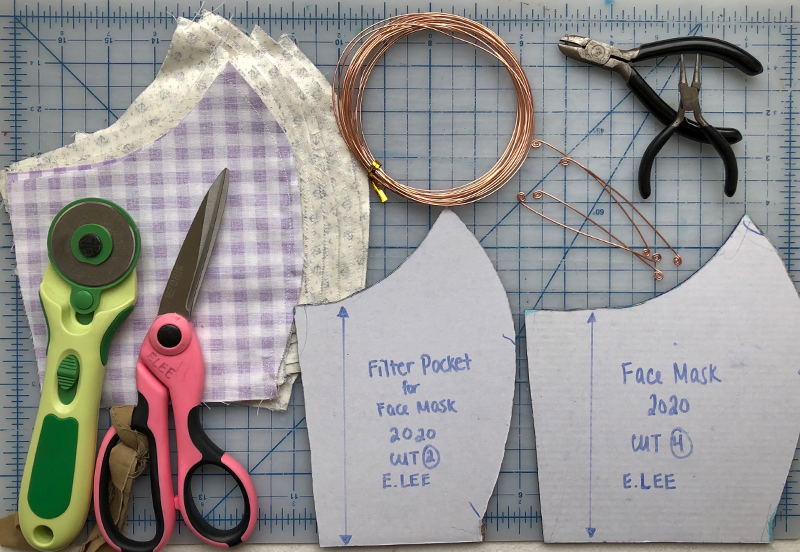

How should I construct the mask?

MATERIALS

- 100% cotton fabric (shell & filter pocket)

- spandex fabric (ear straps)

- 1mm aluminum wire (adjustable nose bridge)

PATTERN-MAKING

- pleated mask

- olson mask

- ear straps

CUT & SEW

- cut patterns and ear straps

- sew pattern pieces and loop the ear straps

A/B TEST

- performance

- likes and dislikes

- lead-time

PRODUCTION

- prepare materials and pattern pieces

- sew in bulk

- deliver

Using spandex for the ear straps is soft on the ears. Ear ties around the neck and head reduce pressure on the ears. Both methods can prevent ear sores. The aluminum wire is sturdy but adjustable to fit the nose.

Tightly woven 100% cotton fabric works best in blocking micro droplets and particles. All mask designs have 3 layers of fabric with a filter pocket for additional protection.

Masks can be handwashed or placed in the washer-dryer to be cleaned and used again.

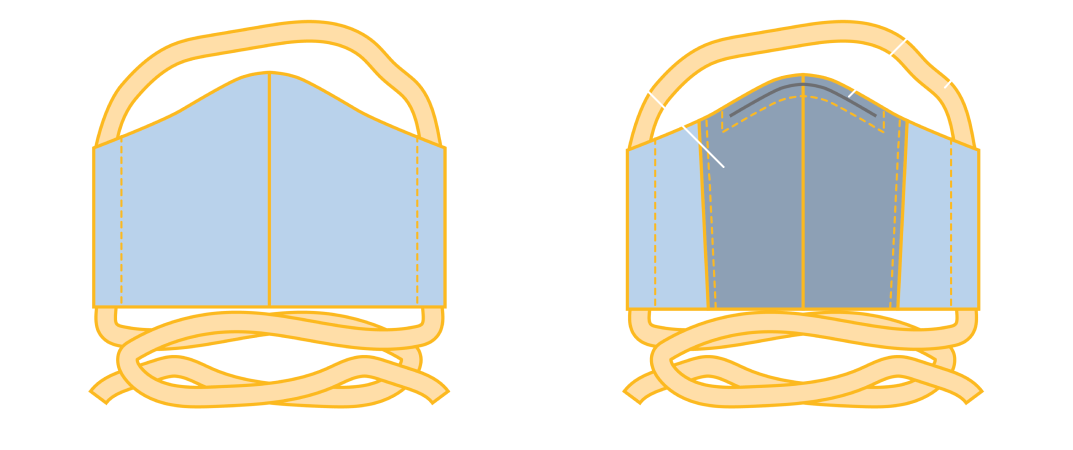

DESIGN #1: Olson Mask with Ear Ties

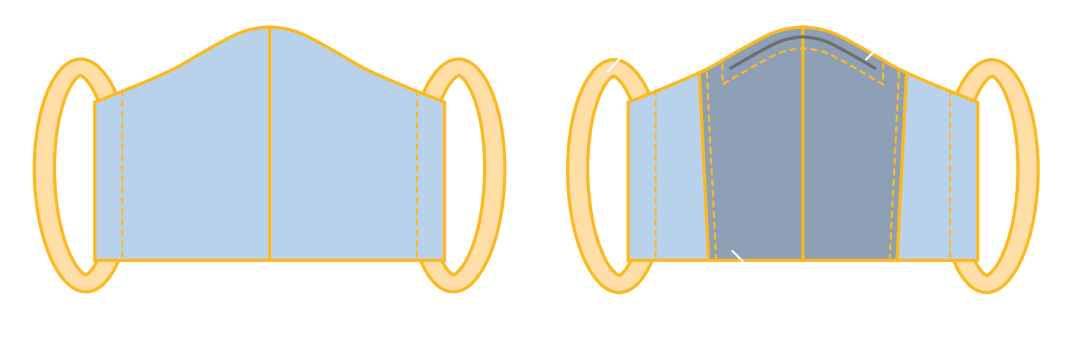

DESIGN #2: Olson Mask with Ear loops

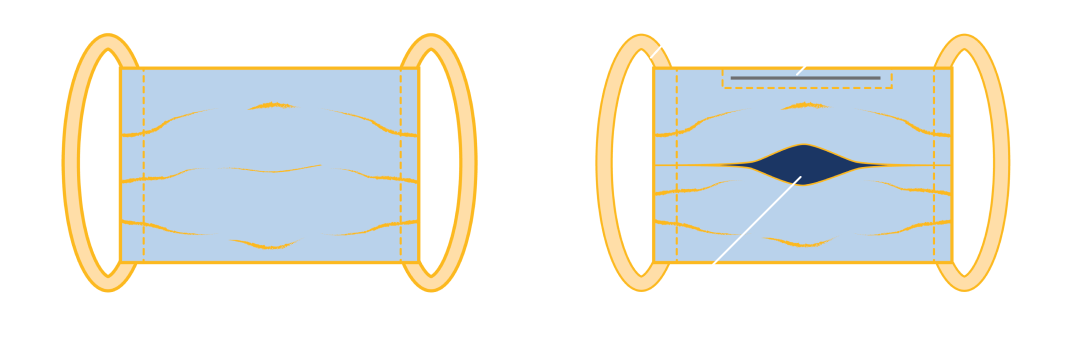

DESIGN #3: Pleated Mask with Ear Loops

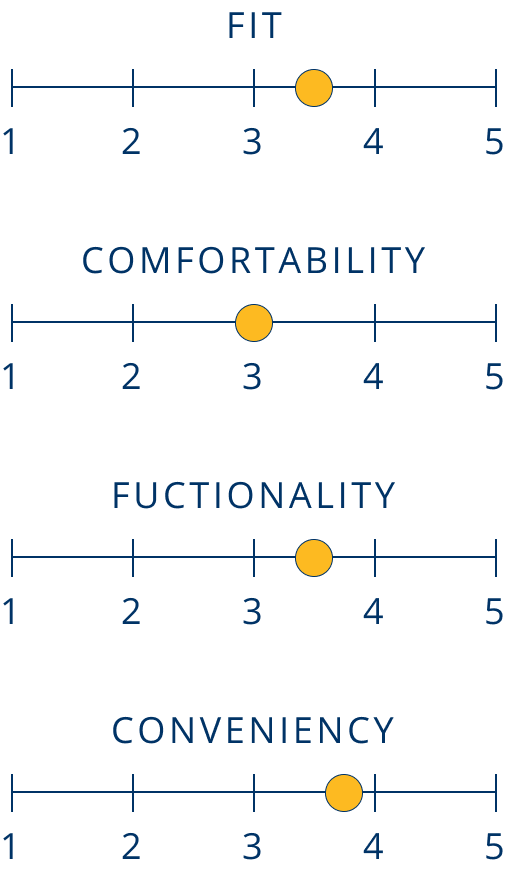

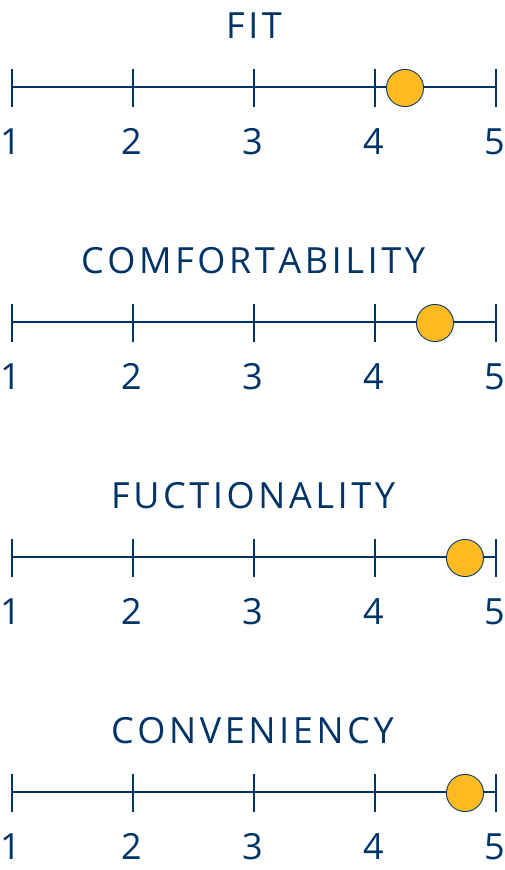

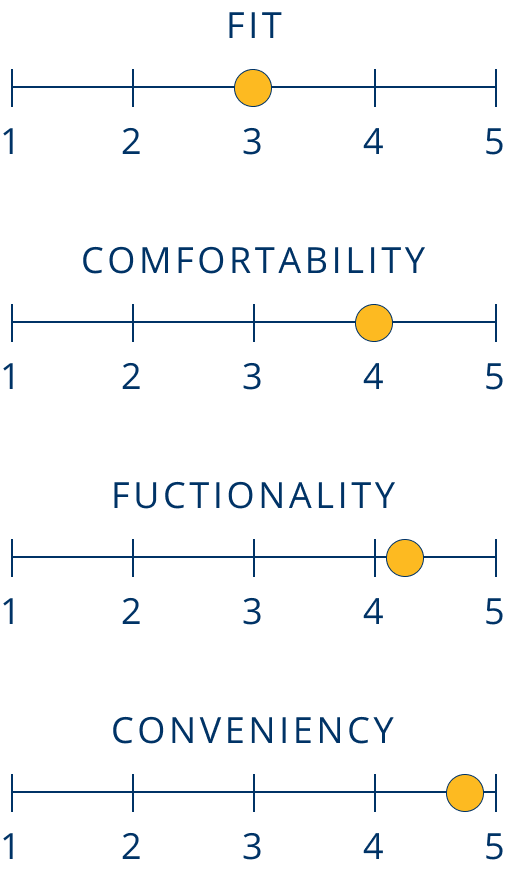

A/B Testing: Which mask design works best?

Each mask was tested on 4 users for fit, comfortability, functionality, and conveniency. A scoring system helped identify which mask scored the highest. The mask with the highest score would then be produced in bulk.

Olson Mask with Ear Ties

Production Time: 10min

3.44

SCORE

"The mask fits well, but the ties can be difficult. I have to adjust the ties each time I put it on and take it off."

Olson Mask with Ear Loops

Production Time: 8.5min

4.56

SCORE

"The ear straps are comfortable and I love the adjustable nose piece. It’s easy to place a filter or surgical mask inside the filter pocket."

Pleated Mask with Ear Loops

Production Time: 8.5min

4.0

SCORE

"Placing a filter inside the pleated mask is inconvenient, whereas the filter pocket on the Olson masks makes it easier to place a filter."

Production: Olson Mask with Ear Loops

Prepare all materials in bulk: one batch of 25 units.

Create cardboard patterns to efficiently trace pattern pieces, then cut.

Cut and bend 5" aluminum wire pieces. Measure and cut ½"x8" spandex strips for ear loops.

Sew shell and filter pocket pieces together, remembering to insert the aluminum wire in‑between the layers.

Press the sewn masks with an iron for smooth crisp edges.

Use a safety pin to loop the spandex strips through each end of the mask. Tie and hide the knot inside the casing.

Repeat steps 1-4 three more times for a total of 100 units.

Deliver masks to medical staff, essential workers, and loved ones.

"Most people have changed their coming into work/going home mask to your mask aka everyone loves it and keeps using them."

"I've been trying to order masks for the past months unsuccessfully. Your gesture took a lot of frustration and stress out of the process. Keep up your efforts."

"Thank you for being so active towards the cause! You are taking your talents and putting it towards helping others in a huge way thats amazing!"